shop drawings definition engineering

It is the short form of Issued for construction. A shop drawing is a drawing set of drawings produced by the contractor check Examples of these include.

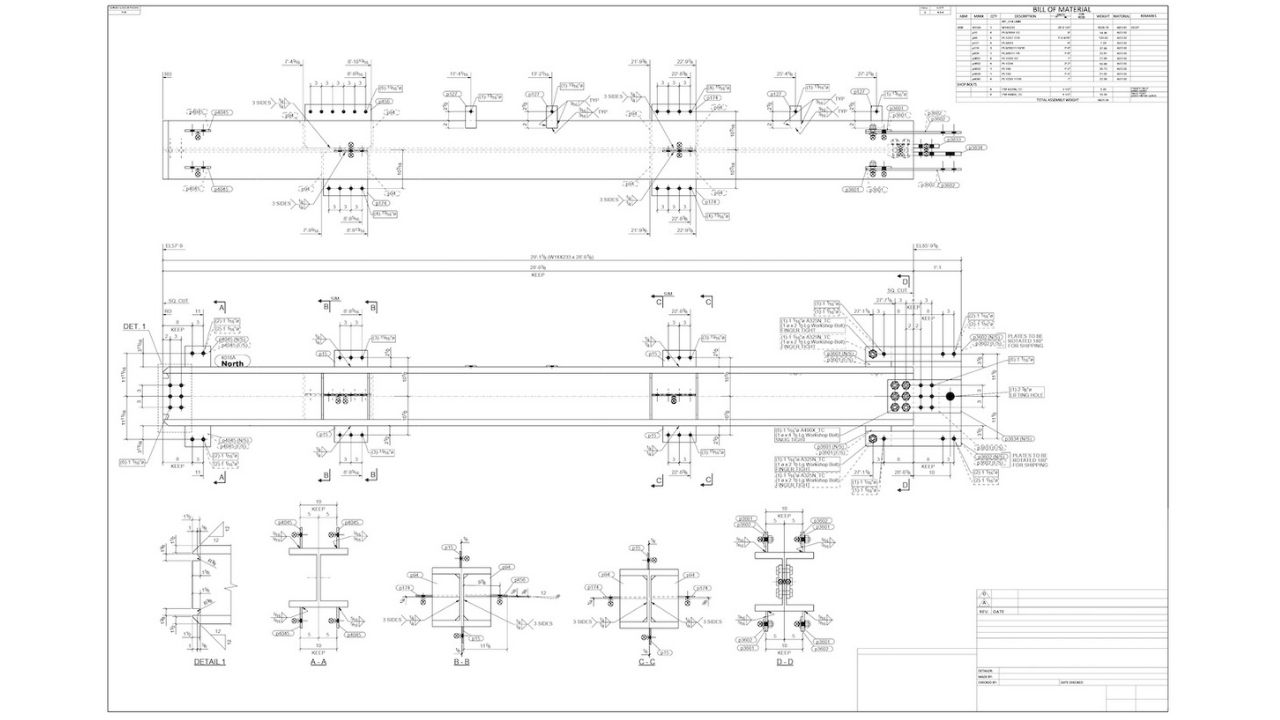

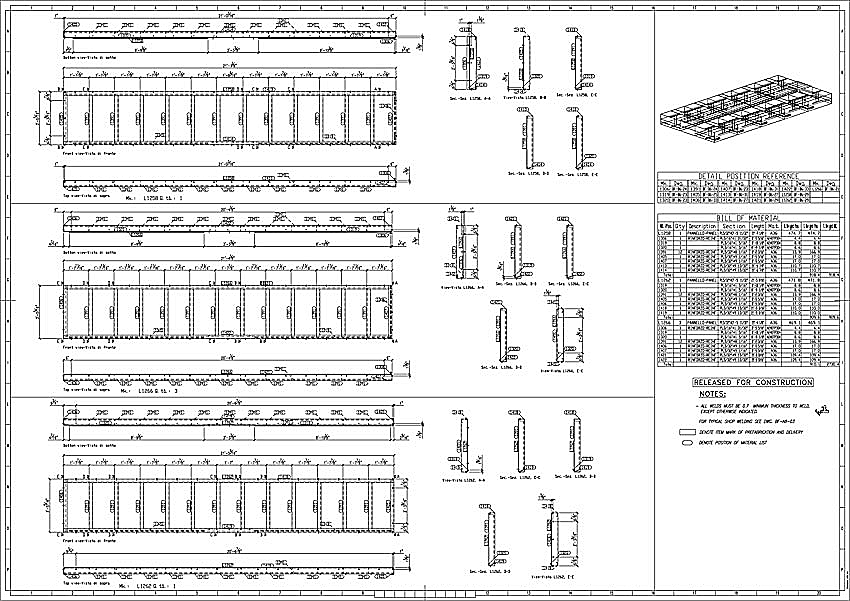

Shop drawings might be prepared for components such as structural steelwork reinforcement lifts building services equipment appliances ductwork piping plumbing windows cabinets electrical and data layouts fire protection and so on.

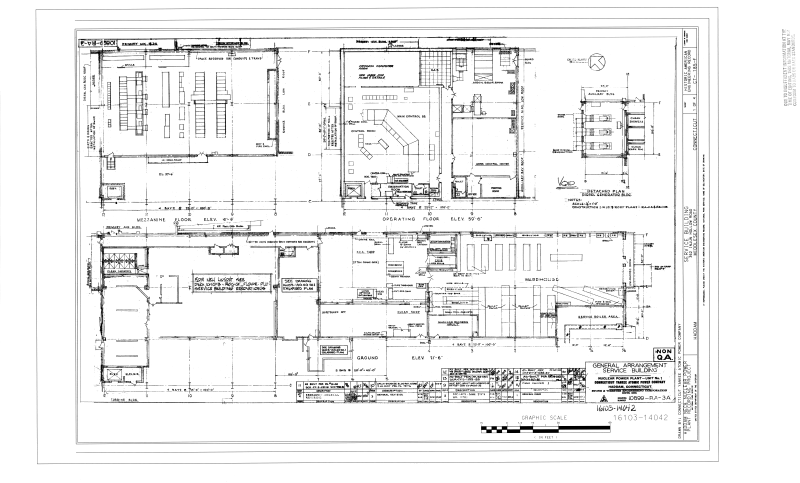

. They depict how the building has been constructed on paper. One of the most common questions that engineers-and architects-ask is whether to mark shop drawings and other submittals approved or whether to take some lesser action. An engineering drawing is a subcategory of technical drawings.

One sees here the basic difference between how engineers look at shop drawings and the way contractors often view them. The difference between pre-and post-development is recognized by as-built drawings. ASME Y14100 Engineering Drawing and Related Documentation Practices was adopted on 30 January 1998 for use by the Department of Defense DoD.

Proposed changes by DoD activities must be submitted to the DoD. The American Institute of Architects AIA family of contracts defines shop drawings as drawings diagrams schedules and other data specially prepared by a distributor supplier manufacturer subcontractor or contractor to show some part of the work. Whereas a shop drawing is the drawing made by the contractors engineering department and issued on site for the site supervisors and foremen to understand easily and implement.

While shop drawings deliver the in-depth instructions and specifications required by a fabricator to. Shop drawings on the other hand are used by fabricators to know how the components will be manufactured and installed during the construction process. The shop drawings must indicate the codes that have been used in the preparation of the shop drawings.

A complete clean set of drawings that reflect how the project was built - folding the as-built revisions into the design documents including addenda post bid bulletins and design revisions. Shop Drawing means any and all drawings diagrams layouts explanations illustrations manufacturer s drawings or other written or graphic materials which illustrate any portion of the construction work. This is an area in which legal advice has changed over the years.

Shop Drawings T he review and approval ofshop drawings is a careful and methodical process. FRIEDLANDER Schiff Hardin Waite Chicago November 1 2000. A good design drawing can indicate all the details needed to produce a mechanical CNC milling part in an easy way.

Submittals which include shop drawings and other administrative documents are how the. Elevators structural steel trusses pre-cast windows appliances cabinets air handling units and millworkAlso critical are the installation and coordination shop drawings of the MEP trades such as sheet metal ductwork piping plumbing fire protection. Which defined measured drawing similarly to the current definition.

The measured drawing gives a description of some detail element of architecture or building. What is IFC Drawing. The dates of all applicable revisions.

Design drawings enable an architect or engineer to communicate their vision for a project. Engineers review shop drawings to increase the likelihood that defects or deficiencies in the. A working drawing is a part of production information provided by the designers to the construction team to help construct a project.

10 7-1 Acronyms for Special Items. Where applicable the project address. They represent enhanced specifications for installing and fabricating ducts custom piping connections.

Mechanical shop drawings demarcate heating vents and air conditioning systems and determine their placement. Engineering Drawing Basics Explained. These are compiled by the designer from the as-built drawings submitted by the contractor as a record of the work.

Shop drawings must include the following information. What is a shop drawing. Shop Drawings means drawings submitted to the PHA by the Contractor subcontractor or any lower tier subcontractor showing in detail 1 the proposed fabrication and assembly of structural elements and 2 the installation ie form fit and attachment details of materials of equipment.

Because there is no large space on a drawing to contain all the text to illustrate the image abbreviations and symbols are often used in engineering drawings to communicate the characteristics of the product to be manufactured. Design drawings and shop drawings both play an essential role in the lifecycle of steelworkwhether it is for a bridge stadium tank or pipework. Shop drawings also known as fabrication drawings are detailed plans that translate design intent.

Shop Drawing means a diagrammatic pictorial or written description of the details of proposed materials equipment components. The HVAC Heating Ventilation and Air Conditioning shop drawings are part of the mechanical shop drawings. 3-1 Example of Common Product Definition Elements for Drawing Graphic Sheets and Data Sets.

This is the drawing is given by the consultant for construction purposes as well as preparation of shop drawings to the. On the completion of the engineering design upto 100 the drawings are issued to the contractor to startup the installations are known as IFC drawings or IFC Package. It can be said that the as-built drawings are needed to compare what was originally planned and what has been made in the end.

Shop drawings also help engineers determine whether the contractor understands the requirements of the plans and specifications. They may be reviewed by the project design team prior to fabrication to verify that they comply with. The purpose is to convey all the information necessary for manufacturing a product or a part.

The original date of issue. Risk management advisers recommend that architecture and engineering professionals use the term record drawing saying there is o such thing as an as-built. Engineering drawings use standardised language and symbols.

Shop Drawing Approval Liability. As-Built drawings are made after the building has been constructed. This makes understanding the drawings simple with little to no personal.

After checking structural steel shop drawings for nearly 30 years I have developed my approach to the procedure based on the one that is described in the AIA General Conditions of the Contract of Con-struction as follows.

The Importance Of Shop Drawings

What Is Shop Drawings Why Is It Important

The Difference Between Design Drawings And Shop Drawings

General Arrangement Drawing Designing Buildings

Shop Drawings Designing Buildings

Plumbing Shop Drawings Advenser

Shop Drawings Definition Use Examples Software Alternatives

Shop Drawings Of Construction Project I Type Of Shop Drawings Iram Hameed Rather Youtube

Mep Shop Drawings What Are They And What Are Their Benefits

The Importance Of Shop Drawings

What Is The Difference Between Ga Drawings And Shop Drawings Quora

Importance Of Shop Drawings In Construction Indovance Blog

Shop Drawings Definition Use Examples Software Alternatives

Electrical Shop And Fabricatrion Drawings Advenser

Difference Between Shop Drawings Ifc Drawing

Plumbing Shop Drawings Advenser